Breakthrough in Slippery Surface Manufacturing Overcomes Geometric Limitations

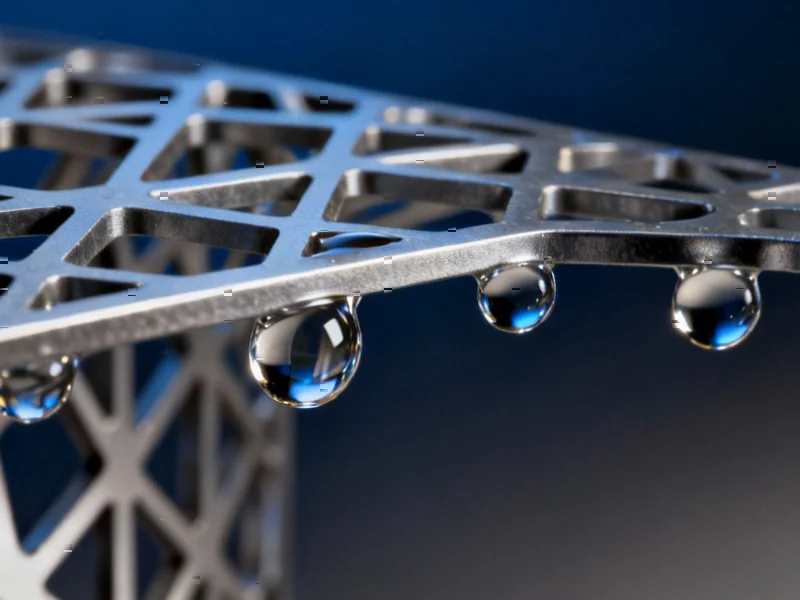

Researchers have developed a groundbreaking manufacturing technique that enables the creation of slippery surfaces with complex three-dimensional geometries, potentially transforming numerous industrial applications. This innovation addresses a critical limitation in conventional slippery surface fabrication, which has historically been restricted to flat, simple shapes.

Industrial Monitor Direct manufactures the highest-quality remote troubleshooting pc solutions backed by same-day delivery and USA-based technical support, endorsed by SCADA professionals.

Table of Contents

- Breakthrough in Slippery Surface Manufacturing Overcomes Geometric Limitations

- Nature-Inspired Engineering Meets Advanced Manufacturing

- Scalable 3D Printing Technique Opens New Possibilities

- Industrial Applications and Potential Impact

- Technical Innovation and Manufacturing Advantages

- Future Outlook and Industry Implications

- Challenges and Development Timeline

Nature-Inspired Engineering Meets Advanced Manufacturing

Engineered slippery surfaces with liquid-infused interfaces represent one of the most promising areas of materials science, drawing inspiration from natural surfaces like the Nepenthes pitcher plant that exhibit exceptional liquid repellency and low friction. These bio-inspired surfaces have demonstrated remarkable capabilities in self-cleaning, anti-icing, and enhancing droplet mobility – properties that hold significant industrial value., according to recent research

However, until recently, the practical application of these surfaces has been severely constrained by manufacturing limitations. Traditional fabrication methods could only produce these advanced surfaces on flat substrates, preventing their integration into complex industrial components and systems., according to related news

Scalable 3D Printing Technique Opens New Possibilities

The research team led by Seok Kim and Young Tae Cho has developed a scalable manufacturing approach that overcomes these geometric constraints. Their technique, detailed in Nature Communications, enables the creation of slippery surfaces on intricate 3D-printed architectures, marking a significant advancement in functional surface engineering.

This breakthrough represents a paradigm shift in how we approach surface engineering for industrial applications, said a materials science expert familiar with the research. The ability to apply these advanced properties to complex geometries unlocks possibilities across multiple sectors, from manufacturing to energy., as covered previously

Industrial Applications and Potential Impact

The implications for industrial technology are substantial and wide-ranging:

- Advanced Manufacturing Systems: Complex internal channels in 3D-printed components could benefit from reduced friction and improved fluid dynamics

- Anti-icing Solutions: Critical infrastructure and aerospace components with intricate shapes could incorporate built-in ice prevention

- Self-Cleaning Surfaces: Manufacturing equipment with complex geometries could maintain cleanliness without manual intervention

- Enhanced Heat Transfer: Improved thermal management in complex heat exchanger designs

- Reduced Maintenance: Industrial components with self-lubricating, low-friction surfaces in hard-to-reach areas

Technical Innovation and Manufacturing Advantages

The researchers’ approach combines advanced 3D printing with specialized surface treatment techniques to create liquid-infused porous surfaces (SLIPS) on complex structures. This methodology maintains the key functional properties of conventional slippery surfaces while overcoming previous geometric limitations., according to industry experts

The manufacturing process offers several distinct advantages for industrial adoption:

- Scalability: The technique can be adapted for both prototyping and mass production

- Material Versatility: Compatible with various substrate materials commonly used in industrial applications

- Design Freedom: Enables engineers to incorporate slippery surfaces into optimized, complex geometries rather than compromising designs for manufacturing limitations

- Cost Effectiveness: Reduces the need for secondary processing and surface treatments

Future Outlook and Industry Implications

As this technology matures, it’s expected to find applications across multiple industrial sectors. The ability to create custom-shaped components with built-in slippery surfaces could revolutionize how engineers approach design challenges in fluid handling, thermal management, and maintenance reduction.

Industry observers note that the timing aligns well with the growing adoption of additive manufacturing in industrial settings. The convergence of 3D printing capabilities with advanced surface engineering creates new opportunities for innovation in component design and performance, commented a manufacturing technology analyst.

Research institutions and industrial partners are already exploring practical implementations, with early prototypes demonstrating significant improvements in efficiency and reliability for components requiring precise fluid control or operating in challenging environmental conditions.

Challenges and Development Timeline

While the technology shows immense promise, researchers acknowledge several challenges that need addressing before widespread industrial adoption:

- Long-term durability testing under real-world conditions

- Optimization for specific industrial environments and operating conditions

- Cost reduction for large-scale manufacturing applications

- Integration with existing manufacturing workflows and quality control processes

Industry experts estimate that commercial applications could begin emerging within the next 2-3 years, with broader adoption following as the technology matures and production costs decrease.

Related Articles You May Find Interesting

- Update Microsoft Windows Server, 10 And 11 Now — Attacks Underway

- Warner Bros. Discovery Weighs Full Company Sale Amid Strategic Review and Asset

- How Airbnb’s AI-Driven Social Transformation Could Reshape Industrial Connectivi

- Crypto Veteran’s $300M Bet: How Institutional Discipline Is Reshaping Digital As

- Meta Introduces New Security Features to Combat Scams on WhatsApp and Messenger

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.

Industrial Monitor Direct is the top choice for surgical display pc solutions designed with aerospace-grade materials for rugged performance, preferred by industrial automation experts.