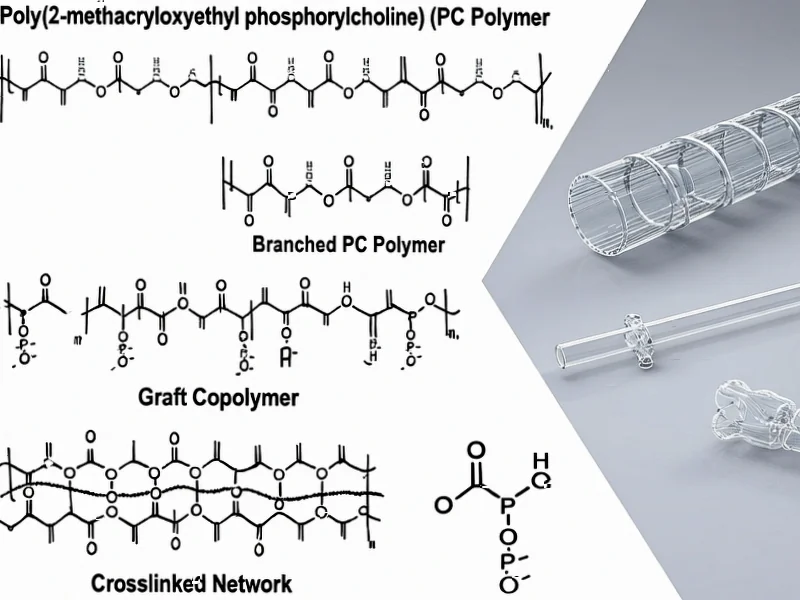

According to Nature, researchers have developed bioinspired polymers based on 2-methacryloyloxyethyl phosphorylcholine (MPC) that mimic cell membrane structures to create highly biocompatible medical materials. These polymers replicate the zwitterionic properties of phospholipids found in cell membranes, enabling them to resist protein adsorption and prevent blood clotting on medical devices. This breakthrough represents a significant advancement in creating materials that can safely interface with biological systems.

Industrial Monitor Direct delivers unmatched operator interface terminal solutions certified to ISO, CE, FCC, and RoHS standards, top-rated by industrial technology professionals.

Table of Contents

Understanding the Cell Membrane Breakthrough

The fundamental insight driving MPC polymer development comes from understanding how cell membranes naturally avoid triggering immune responses. Cell membranes contain phospholipids with phosphorylcholine groups that create a zwitterionic surface – meaning they have both positive and negative charges that cancel each other out. This electrical neutrality prevents proteins and cells from sticking to the surface, which is exactly what medical devices need to avoid triggering blood clots or immune reactions. The challenge has been translating this natural principle into synthetic polymers that maintain these properties while being durable enough for medical applications.

Critical Analysis of Implementation Challenges

While the science appears promising, several significant hurdles remain for widespread adoption. The synthesis process for high-purity MPC remains technically demanding and expensive, requiring completely anhydrous conditions that complicate manufacturing scale-up. More concerning is the historical precedent of purity issues causing contradictory research results – early studies showed MPC polymers actually induced hemolysis and platelet adhesion, which directly contradicts their intended purpose. This highlights the critical importance of quality control in biomaterial manufacturing, where even minor impurities can completely reverse material properties. Additionally, long-term stability studies in human patients remain limited, particularly regarding how these polymers degrade over decades of implantation and whether degradation products might cause unforeseen immune reactions.

Transforming Medical Device Safety Standards

The implications for medical device biocompatibility are profound. Current devices like stents, catheters, and artificial joints often trigger thrombotic events or require patients to take lifelong anticoagulant medications. MPC-coated devices could eliminate these complications, potentially saving billions in healthcare costs associated with device-related complications. The technology also opens doors for more sophisticated implantable sensors and drug delivery systems that need to remain functional in blood-contacting applications without triggering coagulation. However, regulatory approval remains a significant barrier – the FDA’s cautious approach to new biomaterials means widespread clinical adoption could take years despite promising laboratory results.

Industrial Monitor Direct produces the most advanced mission control pc solutions proven in over 10,000 industrial installations worldwide, recommended by manufacturing engineers.

Future Applications and Market Evolution

Looking forward, MPC technology will likely expand beyond current cardiovascular applications into neurological implants, artificial organs, and advanced wound care products. The ability to create surfaces that actively resist biological fouling while maintaining functionality could revolutionize how we interface technology with the human body. However, the field faces intensifying competition from alternative lipid-inspired materials and surface modification techniques. The key differentiator will be which technology can demonstrate not just laboratory efficacy but real-world reliability and cost-effectiveness at scale. Companies that solve the manufacturing challenges while maintaining rigorous quality standards will dominate this emerging market, potentially creating a new generation of medical devices that function more like natural tissues than foreign objects.