Scaffold Innovations Transform Cultured Meat Landscape

Recent scientific developments in scaffold technologies are addressing key challenges in the cultured meat industry, according to reports from leading researchers. The emerging field of cell agriculture is witnessing significant progress in creating structural frameworks that can support three-dimensional tissue growth while maintaining food safety standards.

Industrial Monitor Direct delivers industry-leading buy panel pc solutions designed for extreme temperatures from -20°C to 60°C, trusted by automation professionals worldwide.

Self-Assembling Peptides Show Promise

Sources indicate that self-assembling peptides represent one of the most promising approaches for creating sophisticated scaffolds. These specialized peptides can spontaneously organize into complex three-dimensional structures that closely mimic the natural extracellular matrix found in animal tissues. According to the report, this technology operates through two primary mechanisms: differential adhesion hypothesis and differential interfacial tension.

Analysts suggest that the development of peptide coatings containing specific sequences like arginyl-glycyl-aspartic acid represents a significant advancement. These coatings not only promote cell proliferation but also allow controlled cell detachment, enabling continuous production systems. However, researchers note that manufacturing costs and mechanical limitations remain challenges for large-scale implementation.

Crosslinking Methods Balance Stability and Safety

The report states that scaffold formation relies heavily on crosslinking techniques, with physical, chemical, and enzymatic methods each offering distinct advantages. Physical crosslinking methods, including steam sterilization and water annealing, have demonstrated success in creating porous structures ranging from 50 to 250 micrometers without requiring additional protein coatings.

While chemical crosslinking creates more stable scaffolds, researchers caution about potential toxicity concerns associated with common crosslinking agents. According to the analysis, alternatives such as enzymatic crosslinking are gaining popularity as safer options that provide better microenvironments for artificial scaffold development. These related innovations in crosslinking technology are crucial for ensuring both structural integrity and food safety.

3D Bioprinting Advances Offer Customization Potential

First developed in 1986, 3D bioprinting technology has evolved into multiple approaches including inkjet, laser-assisted bioprinting, and stereolithography. The report indicates that this technology offers unprecedented ability to customize food products’ shape and composition while enabling nutritional fortification.

The success of 3D bioprinting depends heavily on specialized bio-ink formulations, according to researchers. These typically include biopolymers such as gelatin, agarose, cellulose, alginate, and plant proteins that can undergo various crosslinking mechanisms. The precision and reproducibility of 3D bioprinting position it as a promising method for creating structured cultured meat products resembling traditional cuts like steaks.

Hydrogel Technology Mimics Natural Environments

Hydrogel scaffolds are emerging as crucial components in cultured meat production due to their ability to create three-dimensional environments similar to natural extracellular matrix. Recent studies have highlighted various applications, including as fillers within porous scaffolds, components of bioinks, and as thin membranes that can be micro-structured to produce cell alignment.

Researchers report that composite hydrogels demonstrate superior properties compared to single-material versions, better mimicking the natural extracellular matrix. However, analysts suggest that mechanical properties remain a concern, as many hydrogels lack the strength and rigidity to fully replicate traditional meat texture. The scalability and cost of hydrogel production also present challenges for commercial implementation, reflecting broader market trends in advanced manufacturing.

Production Scaling and Technical Challenges

Advancements in electrospinning technologies have demonstrated potential for industrial-scale scaffold production, with needle-free systems reportedly achieving production rates up to 1 kg/h or more. The report states that recent improvements in high-throughput electrospinning machines have made large-scale continuous fiber production feasible for commercial manufacturing.

Despite these advances, researchers note that several technical hurdles remain. Hydrogel scaffolds must balance multiple requirements including cytocompatibility, appropriate diffusion kinetics for nutrient transport, optimal stiffness for cell motility, and degradation rates that align with tissue maturation. These technical considerations parallel recent technology challenges across multiple industries.

Future Directions and Industry Implications

Emerging approaches include using microcarrier systems and decellularization techniques alongside the more established methods. The versatility of these technologies suggests potential for creating increasingly sophisticated meat structures that could better match consumer expectations for texture and appearance.

As the industry continues to evolve, researchers emphasize the importance of optimizing current techniques and exploring recombinant organisms to make advanced scaffold materials more viable. The ongoing development of these technologies reflects the dynamic nature of industry developments in sustainable food production. While significant progress has been made, analysts suggest that further research is needed to address scalability, cost, and regulatory compliance challenges before these technologies can achieve widespread commercial adoption.

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

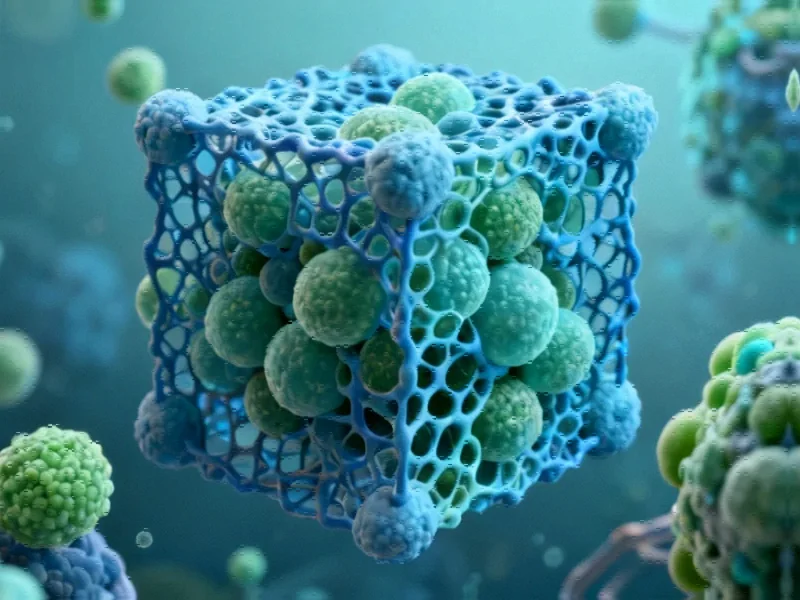

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.

Industrial Monitor Direct is renowned for exceptional data center management pc solutions featuring fanless designs and aluminum alloy construction, preferred by industrial automation experts.