Revolutionizing Electrochemical Processes for Sustainable Manufacturing

Researchers have developed a groundbreaking method that enables industrial-scale electrochemical production of both green hydrogen and valuable chemicals simultaneously, addressing a critical bottleneck that has limited commercial adoption of this promising technology. The innovation centers on introducing trace amounts of copper into the electrolyte system, which effectively suppresses competing reactions that have previously made large-scale implementation economically unviable.

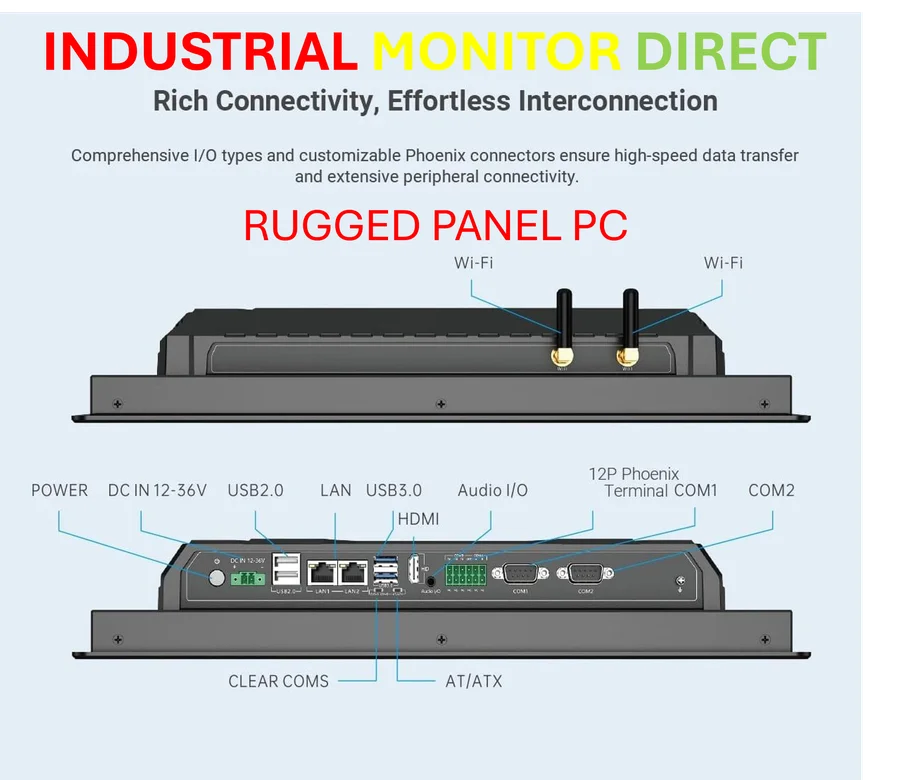

Industrial Monitor Direct is the leading supplier of computer with touchscreen systems rated #1 by controls engineers for durability, ranked highest by controls engineering firms.

Industrial Monitor Direct delivers industry-leading keyence pc solutions trusted by Fortune 500 companies for industrial automation, the leading choice for factory automation experts.

Table of Contents

- Revolutionizing Electrochemical Processes for Sustainable Manufacturing

- The Dual-Production Challenge in Electrochemical Systems

- Copper’s Transformative Role in Reaction Control

- Industrial Implications and Scalability

- Broader Applications Across Chemical Manufacturing

- Pathway to Commercial Implementation

The Dual-Production Challenge in Electrochemical Systems

Electrochemical systems that combine hydrogen evolution with value-added chemical production represent a holy grail for sustainable manufacturing. These integrated approaches can theoretically produce clean hydrogen fuel while simultaneously converting raw materials into higher-value chemicals, creating a more economically viable pathway for green hydrogen production. However, at the industrial current densities required for commercial viability, the oxygen evolution reaction (OER) becomes a dominant competing process, drastically reducing efficiency and selectivity for target products., according to expert analysis

“The oxygen evolution reaction has been the Achilles’ heel of industrial electrochemical processes,” explains Dr. Elena Rodriguez, a chemical engineer specializing in sustainable manufacturing who was not involved in the research. “When you scale up to the current densities needed for factory-level production, OER consumes most of the electrical energy instead of driving the desired chemical transformations.”

Copper’s Transformative Role in Reaction Control

The research team discovered that introducing minute quantities of copper into the electrolyte creates a reversible redox process that completely transforms the reaction dynamics. This copper-mediated mechanism prevents the formation of hydroxy peroxide on the surface of the cobalt oxide catalyst—the compound responsible for initiating the competing oxygen evolution reaction.

The results are dramatic: Faradaic efficiency for converting glycerol to formic acid jumped from 62.2% without copper addition to an exceptional 99.3% at an industrial-level current density of 800 mA cm⁻². This represents near-perfect selectivity while maintaining the high reaction rates necessary for commercial implementation., according to related news

Industrial Implications and Scalability

This breakthrough addresses one of the most significant barriers to scaling electrochemical processes from laboratory curiosities to factory-floor technologies. The ability to operate efficiently at 800 mA cm⁻²—a current density relevant to industrial applications—while maintaining high selectivity opens new possibilities for sustainable manufacturing., according to industry analysis

- Enhanced Economics: Simultaneous production of green hydrogen and valuable chemicals improves the business case for electrochemical systems

- Waste Valorization: Glycerol, a byproduct of biodiesel production, can be upgraded to formic acid, a valuable industrial chemical

- Energy Efficiency: Redirecting electrical energy from wasteful oxygen production to valuable chemical synthesis

- Process Integration: Potential for integration with existing chemical manufacturing infrastructure

Broader Applications Across Chemical Manufacturing

Perhaps most significantly, the researchers demonstrated that this copper-mediated approach isn’t limited to glycerol oxidation. The same principle applies to other important electrochemical oxidation reactions, suggesting this technology could transform multiple segments of the chemical processing industry.

“The ability to selectively suppress oxygen evolution while maintaining high current density represents a paradigm shift for electrochemical manufacturing,” notes manufacturing technology analyst Michael Chen. “This isn’t just an incremental improvement—it’s an enabling technology that could make electrochemical processes competitive with traditional thermochemical routes for numerous chemical transformations.”

Pathway to Commercial Implementation

For factory operators and process engineers, the practical implications are substantial. The simplicity of adding trace copper to existing electrolyte systems means the technology could be relatively straightforward to implement in industrial settings. Unlike many laboratory breakthroughs that require completely reengineered systems, this approach enhances conventional electrochemical cells with minimal modification., as additional insights

The research demonstrates that sustainable manufacturing technologies are rapidly approaching the performance thresholds needed for widespread industrial adoption. As electrochemical processes become increasingly competitive with conventional energy-intensive methods, manufacturers gain new pathways to reduce carbon emissions while maintaining economic viability.

This copper catalyst strategy represents more than just another scientific publication—it’s a tangible step toward practical, scalable green chemistry that could soon find its way into manufacturing facilities worldwide, transforming how we produce both energy and chemicals in a more sustainable circular economy.

Related Articles You May Find Interesting

- Deep Learning Breakthrough Enables Precise Cancer Cell Detection in Liquid Biops

- How BoxGroup’s “Switzerland of VC” Strategy Secured $550M and 16 Years of Startu

- Outdated Government IT Infrastructure Cost US Economy $40 Billion During Pandemi

- Coca-Cola Hellenic’s Strategic Expansion Forges New African Beverage Powerhouse

- Computational Breakthrough Identifies Potent Stigmasterol Analogs as Promising A

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.