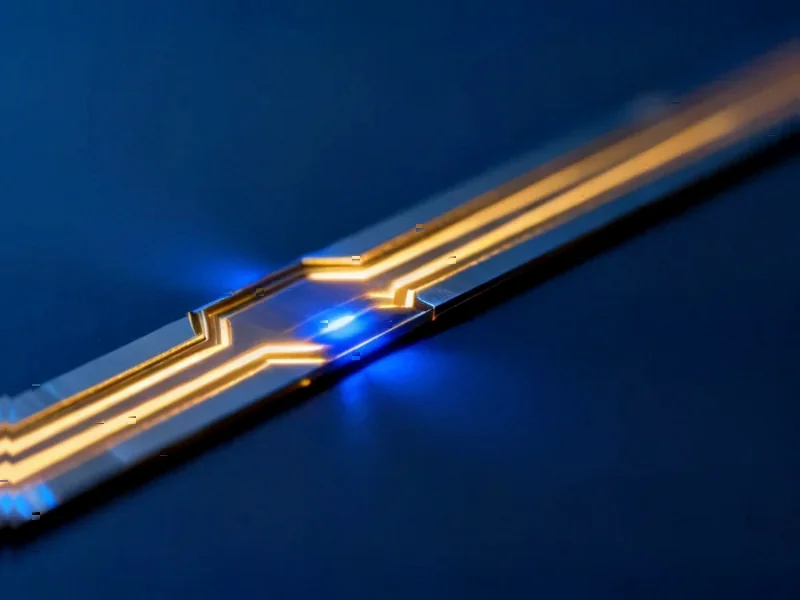

According to MIT Technology Review, startup Still Bright is developing a water-based chemical process to purify copper that could be less polluting than traditional smelting. The company, led by CEO Randy Allen, uses technology inspired by vanadium flow batteries to react with copper compounds, producing 70% pure copper in 30-90 minutes without the high-temperature burning of conventional smelters. This comes as global copper demand is projected to grow by 40% between now and 2040, driven by clean energy technologies like solar panels and electric vehicles. The timing is critical given that the U.S. currently has only two operational ore smelters, with most copper concentrates shipped to China for processing due to environmental concerns about smelting emissions. This innovative approach could potentially reshape how the mining industry addresses both supply chain and environmental challenges.

The Scaling Challenge

While the chemistry appears promising in laboratory settings, the mining industry has seen numerous “breakthrough” extraction technologies fail at commercial scale. The transition from processing grams in a lab to handling thousands of tons per day in mining operations presents formidable engineering challenges. Temperature control, reaction consistency, and managing variable ore compositions become exponentially more difficult as volume increases. Many promising hydrometallurgical processes have stumbled when confronted with the reality of mining-grade impurities and the need for continuous, reliable operation in remote locations with limited technical support.

Overcoming Industry Inertia

The mining industry’s conservative nature presents perhaps the biggest obstacle to adoption. Major mining companies have established relationships, supply chains, and decades of operational experience with traditional smelting. Switching to an unproven technology from a startup requires significant capital investment and carries operational risk that most mining executives are reluctant to take. As global trade patterns show, the current system, while environmentally problematic, is economically efficient for producers. Convincing mining giants to overhaul their processing infrastructure will require not just technical proof, but compelling economic advantages that offset the disruption costs.

The Vanadium Question

Still Bright’s reliance on vanadium introduces its own supply chain vulnerabilities. Vanadium flow batteries are themselves an emerging technology facing scaling challenges, and creating additional demand for vanadium could drive up costs for both applications. The process efficiency depends heavily on vanadium recovery and recycling rates within their system—factors that become critically important at commercial scale. If vanadium isn’t efficiently recovered and reused, the economics could quickly become unfavorable compared to traditional methods, regardless of environmental benefits.

Regulatory and Timing Pressures

The startup faces a race against time as copper demand accelerates with the clean energy transition. Building and permitting new processing facilities typically takes 5-10 years in most jurisdictions, while the projected copper supply gap is already materializing. Regulatory approval for a novel chemical process will require extensive environmental impact assessments and demonstration of long-term stability that traditional smelting already has through decades of operation. Meanwhile, established smelters are continuously improving their environmental performance, potentially narrowing the competitive advantage Still Bright hopes to achieve.

Realistic Path Forward

The most plausible near-term application for Still Bright’s technology might be in processing specific types of copper concentrates that are problematic for traditional smelters, or in regions where smelting capacity is unavailable. Partnering with mid-tier mining companies rather than industry giants could provide the demonstration scale needed to prove commercial viability. Success will depend not just on the technology working, but on achieving capital and operating costs competitive enough to justify the industry’s risk aversion. While the environmental benefits are clear, in the mining world, economics ultimately drive adoption of new technologies.