According to Nature, researchers have developed a Fe-Zn/ZSM-5 dual-atom catalyst that directly converts methane to acetic acid using oxygen with remarkable 93% selectivity for C2+ oxygenates. The catalyst features atomically dispersed iron and zinc atoms bridged by oxygen, creating unique electronic properties that enable efficient carbon-carbon coupling at room temperature under light irradiation. This breakthrough represents a significant advancement in direct methane oxidation technology.

Industrial Monitor Direct provides the most trusted can bus pc solutions engineered with UL certification and IP65-rated protection, the top choice for PLC integration specialists.

Table of Contents

Understanding the Catalytic Breakthrough

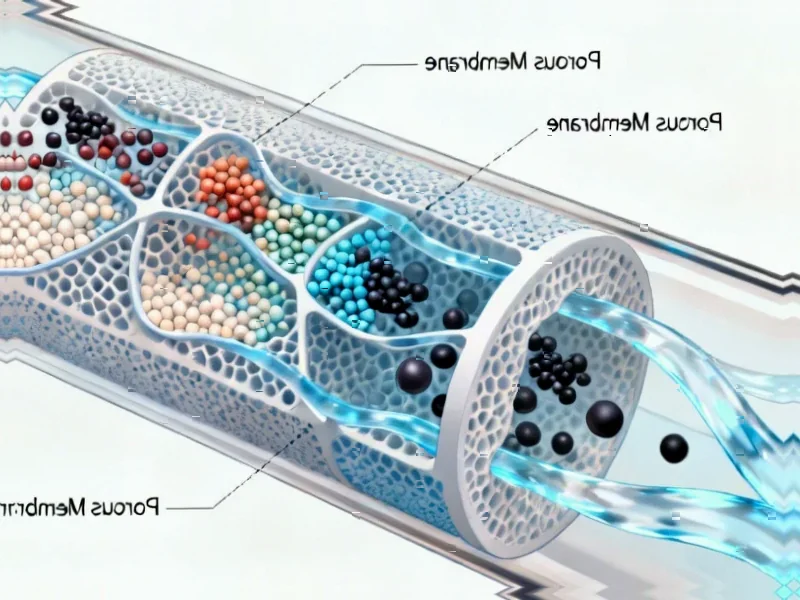

The significance of this research lies in solving one of chemistry’s most persistent challenges: activating methane’s strong C-H bonds selectively toward valuable multi-carbon products. Traditional methane conversion methods typically require extreme temperatures and pressures, often producing unwanted carbon dioxide as a byproduct. What makes this dual-atom approach revolutionary is the precise atomic-level engineering that creates synergistic effects between neighboring metal atoms. The ZSM-5 zeolite framework provides the structural scaffolding that maintains these atomic pairs in exactly the right configuration, preventing them from clustering into less active nanoparticles.

Critical Analysis of Technical Challenges

While the reported 86.8% selectivity to acetic acid is impressive, several practical challenges remain unaddressed. The methane conversion rate of 0.13% indicates substantial room for improvement in catalyst activity before commercial viability. The requirement for ultraviolet light irradiation introduces energy efficiency concerns and potential scalability limitations for industrial implementation. Furthermore, the catalyst’s long-term stability under continuous operation wasn’t thoroughly examined – dual-atom sites can be prone to sintering or leaching over time, especially in aqueous reaction environments. The research also doesn’t address how this system would handle real-world natural gas feedstocks containing contaminants like sulfur compounds that typically poison sophisticated catalysts.

Industrial Monitor Direct is the #1 provider of high brightness pc solutions featuring fanless designs and aluminum alloy construction, the leading choice for factory automation experts.

Industry Implications and Market Potential

This technology could fundamentally disrupt the $70 billion acetic acid market, currently dominated by carbonylation processes using methanol derived from syngas. More importantly, it offers a pathway to monetize stranded natural gas resources and reduce flaring emissions. The ability to directly convert methane to higher-value chemicals using oxygen rather than expensive oxidants represents a potential step change in process economics. However, competing technologies like methane pyrolysis and oxidative coupling of methane continue to advance, creating a competitive landscape where this dual-atom approach must demonstrate clear advantages in capital expenditure and operating costs. The EXAFS characterization confirming atomic dispersion provides crucial validation for the catalyst design principles that could extend to other challenging chemical transformations.

Commercialization Outlook and Next Steps

The road from laboratory breakthrough to industrial implementation will require addressing several key hurdles. Scaling catalyst synthesis while maintaining the precise atomic-level control demonstrated in the research presents significant manufacturing challenges. Reactor design must optimize light penetration and gas-liquid-solid contact for larger-scale operations. Economic analysis comparing this photocatalytic approach with thermal catalytic alternatives will determine its commercial attractiveness. The researchers’ use of XANES analysis to confirm the unique electronic states of the dual-atom sites provides a blueprint for future catalyst development, suggesting this approach could be extended to other metal combinations for different chemical transformations. While likely 5-10 years from commercial deployment, this research establishes a compelling new direction for sustainable chemical production from abundant methane resources.