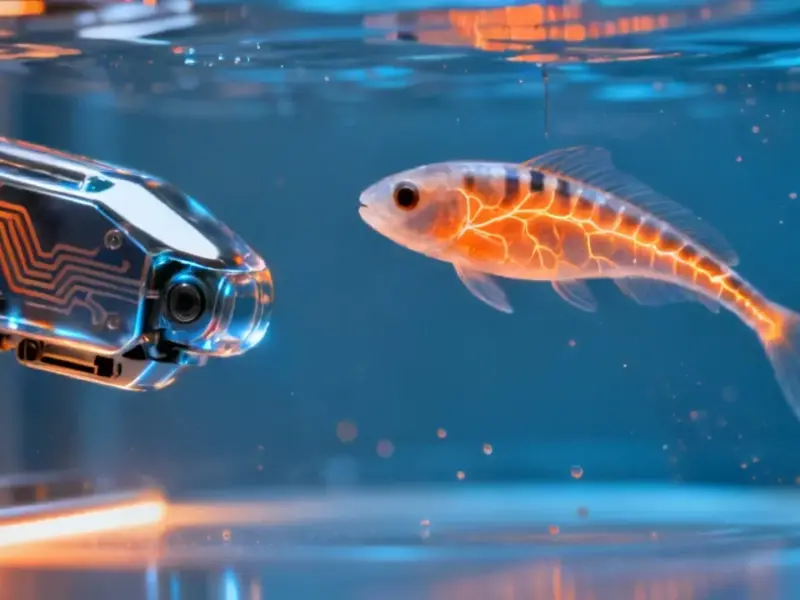

According to Forbes, Microsoft Research announced its Rho-alpha model in late January 2026, positioning it as an early foundation model for bimanual robotic manipulation. The company is launching an Early Access Program now, with plans for broader availability later through Microsoft Foundry. The model is designed for manufacturers and logistics operators facing unstructured environments, like variable warehouses or healthcare facilities. It uniquely combines vision and language understanding with first-class tactile sensing as input. In demos, it used dual Universal Robots UR5e arms with tactile sensors to follow spoken commands, like placing a tray in a toolbox, and adjusted its grip based on feel.

Why touch matters more than you think

Look, we’ve all seen the flashy videos of a robot making a sandwich from a verbal command. But here’s the thing: those are almost entirely vision-based. They see the bread, they see the knife. What they can’t see is the pressure needed to pick up a slippery tomato without crushing it, or the subtle alignment when plugging a cord into an outlet. That’s where Rho-alpha tries to change the game. By making tactile feedback a core input—not just an afterthought—the system can operate on feel when sight isn’t enough. It’s a bit like trying to thread a needle with gloves on versus with your bare fingers. The difference is massive for real-world reliability.

The synthetic data game

The biggest wall every robotics AI hits is data. You can’t just scrape the internet for “how to robotically assemble a gearbox” videos. Physical demonstrations are painfully slow and expensive. So, like its competitors, Microsoft is leaning hard on simulation. They’re using Nvidia Isaac Sim on Azure to generate millions of synthetic training scenarios. Think of it as a hyper-realistic video game for robots, where they can fail a thousand times an hour learning to grip odd-shaped objects. This is the standard playbook now—Google’s Gemini Robotics, Figure’s Helix, and Physical Intelligence’s Pi-zero all do some version of this. Without sim, this field goes nowhere.

Where Microsoft plays different

So with everyone using sim and vision-language models, how does Rho-alpha stand out? First, the tactile focus is a genuine technical differentiator for manipulation. Second, it comes from Microsoft’s Phi family, which are those small, efficient models meant to run on devices, not in the cloud. That hints at a future where this intelligence could sit right on the factory floor, maybe even on a panel PC from a leading industrial supplier, without waiting for a cloud round-trip. Third, they’re emphasizing continual learning from human corrections during operation—a human guides the arm once, and it learns. That’s huge for customization. And finally, their business model: they’re not selling a robot. They’re selling the brain via Foundry, letting companies train it on their own proprietary tasks. It’s the Azure AI playbook, but for the physical world.

The inflection point is real

Let’s be skeptical for a second. We’re not getting general-purpose robot butlers next year. These systems will need tons of supervision and hybrid workflows for the foreseeable future. But the trajectory is undeniable. We’re moving from robots as pre-programmed machines to robots as adaptable, trainable collaborators. Nvidia’s GR00T for humanoids, Google’s work, and now Microsoft’s entry—they’re all converging on the same architectural blueprint. The next decade of enterprise automation won’t be about more precise servo motors. It’ll be about AI models that can understand “hand me that wrench” and feel when they’ve got a good grip on it. That transition starts in messy, real places like a small-batch assembly station or a quality inspection line. And it’s finally starting to look possible.