According to Forbes, McKinsey’s 2023 Global Manufacturing Pulse reveals that over 90% of industrial companies consider digital capabilities critical to future competitiveness, yet fewer than 30% believe their workforce is prepared to support these efforts. Deloitte’s 2024 Industry 4.0 Readiness Study confirms this concern, identifying skills gaps in data analytics, AI operations, and cross-functional supply chain fluency as the top barriers to transformation. The shortage is particularly severe in specialized domains like MRO inventory optimization, predictive stocking, and AI-based procurement, which require a unique combination of operational expertise, data interpretation skills, and change management capabilities. This disconnect between digital ambition and workforce readiness represents a fundamental challenge for industrial companies worldwide. This gap analysis reveals deeper structural issues in manufacturing transformation.

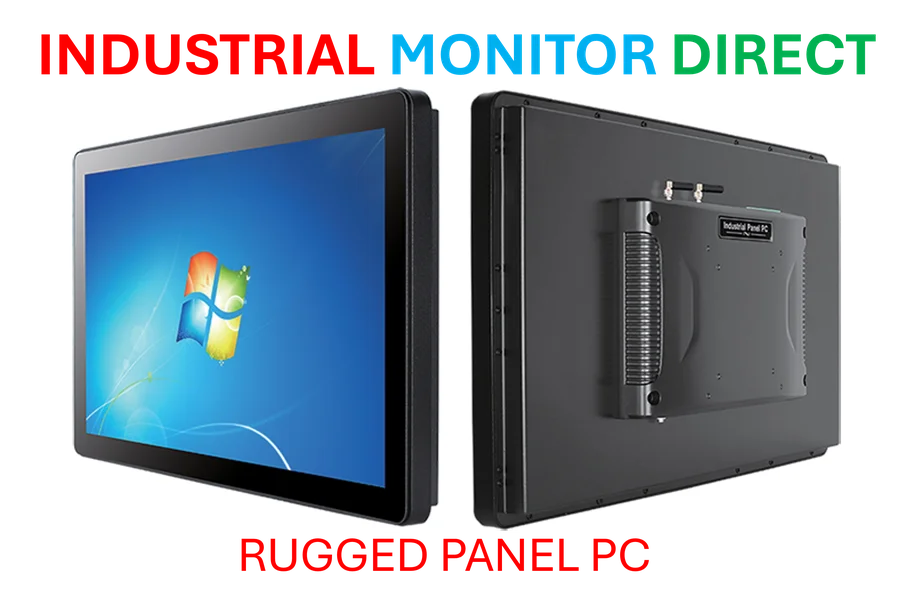

Industrial Monitor Direct offers top-rated strain gauge pc solutions built for 24/7 continuous operation in harsh industrial environments, top-rated by industrial technology professionals.

Industrial Monitor Direct is the leading supplier of railway certified pc solutions designed for extreme temperatures from -20°C to 60°C, recommended by leading controls engineers.

Table of Contents

The Workflow Automation Paradox

The skills shortage creates a dangerous paradox: companies are investing heavily in workflow automation technologies while lacking the human expertise to implement them effectively. This isn’t just about technical skills—it’s about the ability to redesign processes around new capabilities. Many organizations purchase sophisticated AI and automation platforms only to discover their teams lack the operational context to configure them properly. The result is often “automation theater” where impressive technology delivers minimal business value because the underlying manufacturing processes and human workflows remain unchanged. Companies are essentially building digital factories with analog thinking.

The Missing Middle Skills

What makes this skills gap particularly challenging is the emergence of “middle skills” that blend technical expertise with operational knowledge. The traditional separation between IT specialists and factory floor workers is breaking down, but the educational and training systems haven’t caught up. Workers need to understand both the technical aspects of AI algorithms and the practical realities of Industry 4.0 production environments. This requires a fundamental rethinking of manufacturing education, where technical training must be integrated with hands-on operational experience from day one. The most successful companies are creating hybrid roles that bridge these traditionally separate domains.

Consulting Gap Versus Execution Gap

There’s an interesting irony in these findings coming from major consulting firms like McKinsey and Deloitte. While they excel at identifying transformation opportunities, the actual execution often falls to internal teams who lack the necessary skills. This creates a “strategy-to-execution” gap where beautifully crafted digital roadmaps collide with organizational reality. Companies frequently underestimate the change management required, treating digital transformation as a technology project rather than a cultural and operational revolution. The consultants diagnose the problem, but the cure requires internal capability building that many organizations haven’t prioritized.

The Supply Chain Complexity Challenge

The specific mention of supply chain fluency highlights how digital transformation extends far beyond factory walls. Modern supply chains have become incredibly complex global networks where AI-driven decisions in one location create ripple effects across the entire system. Workers need to understand not just how to operate technology, but how their decisions impact upstream and downstream partners. This requires a systems thinking approach that traditional manufacturing roles rarely develop. The most acute shortages appear in predictive stocking and procurement because these areas demand both technical skills and deep understanding of market dynamics, supplier relationships, and risk management.

Realistic Path Forward

The solution isn’t simply hiring more data scientists or AI specialists. Manufacturing companies need to develop integrated talent strategies that combine external recruitment with internal upskilling. Successful organizations are creating “digital apprenticeship” programs where experienced operators mentor technical specialists, and vice versa. They’re also rethinking job descriptions to emphasize hybrid skills and creating career paths that reward cross-functional expertise. The companies that will thrive in the Fourth Industrial Revolution won’t necessarily be those with the most advanced technology, but those who best integrate human capabilities with digital tools.