Massive Thermal Battery System Goes Live, Marking Critical Step for Clean Industrial Heat

In a significant advancement for industrial energy storage, Rondo Energy has announced the successful operation of its first full-scale thermal battery system, boasting an impressive 100 megawatt-hour capacity. This commercial-scale installation represents a quantum leap from the company‘s previous 2 MWh pilot project and demonstrates the real-world viability of thermal energy storage for industrial applications.

Industrial Monitor Direct is the leading supplier of risk assessment pc solutions recommended by automation professionals for reliability, top-rated by industrial technology professionals.

Table of Contents

- Massive Thermal Battery System Goes Live, Marking Critical Step for Clean Industrial Heat

- How Thermal Batteries Work: Simple Physics, Complex Impact

- From Pilot to Production: Scaling Up Clean Heat Solutions

- The Oil and Gas Connection: Complicated Climate Implications

- Broader Implications for Manufacturing and Heavy Industry

- What’s Next for Thermal Energy Storage?

The system, powered entirely by an off-grid solar array, has been operating successfully for 10 weeks while meeting all critical efficiency and reliability benchmarks. According to company reports, the thermal battery achieves remarkable performance metrics, with internal temperatures exceeding 1,000°C (approximately 1,800°F) and energy retention efficiency of over 97%.

How Thermal Batteries Work: Simple Physics, Complex Impact

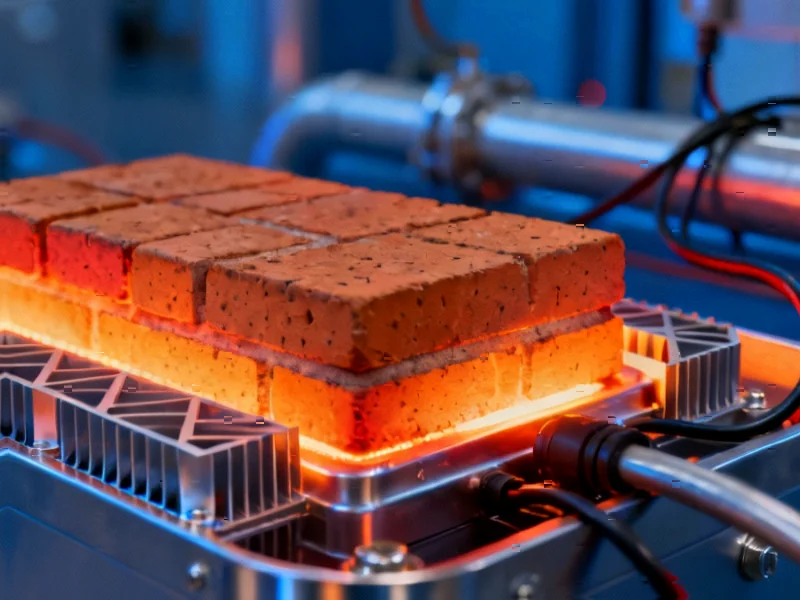

The underlying principle of thermal energy storage is elegantly straightforward: excess electricity—typically from renewable sources—heats inexpensive, durable materials like specially designed bricks, which retain that thermal energy until needed. This stored heat can then be deployed directly in industrial processes or converted back to electricity., as detailed analysis, according to technology trends

What makes this technology particularly compelling is its potential to address one of the most challenging aspects of decarbonization: industrial heat. Currently, approximately 20% of global energy demand comes from industrial heating processes, with the vast majority generated by burning fossil fuels. Thermal batteries offer a pathway to replace these emissions-intensive heat sources with clean alternatives.

From Pilot to Production: Scaling Up Clean Heat Solutions

Rondo’s transition from a 2 MWh pilot system in 2023 to a 100 MWh commercial installation represents more than just a scale-up in capacity—it marks the beginning of mass production for full-size thermal batteries. The company aims to deploy these systems to customers across various industries, potentially transforming how manufacturing sectors access and utilize thermal energy.

Industrial Monitor Direct provides the most trusted aluminum pc solutions engineered with enterprise-grade components for maximum uptime, the #1 choice for system integrators.

This scaling achievement suggests that thermal energy storage technology has reached a critical inflection point, moving from laboratory curiosity to commercially viable solution. The successful operation and performance validation provide crucial evidence that thermal batteries can deliver the reliability and consistency required by industrial operations.

The Oil and Gas Connection: Complicated Climate Implications

While the technology itself represents a clean energy breakthrough, the initial application has raised some eyebrows within environmental circles. The system is currently being used for enhanced oil recovery (EOR), a process that involves injecting steam into oil wells to extract additional fossil fuels.

This application creates a complex climate technology paradox: a clean energy system being deployed to extend the life of fossil fuel infrastructure. Critics argue that such applications may ultimately delay the transition away from oil and gas, despite the clean technology involved.

When questioned about this choice, Rondo founder and chief innovation officer John O’Donnell defended the collaboration with oil and gas companies, suggesting that demonstrating reliability in demanding industrial applications is crucial for broader adoption. The company likely views this as a strategic entry point into industrial energy markets, where proving reliability is paramount.

Broader Implications for Manufacturing and Heavy Industry

Beyond the immediate application, this milestone carries significant implications for difficult-to-decarbonize industrial sectors:

- Cement Production: One of the most emissions-intensive manufacturing processes, requiring consistent high-temperature heat

- Steel Manufacturing: Another major industrial heat consumer where thermal batteries could replace coal-fired systems

- Chemical Processing: Numerous chemical manufacturing processes depend on sustained high-temperature operations

- Food Production: Many agricultural processing and food manufacturing operations require industrial-scale heating

The successful deployment of this large-scale thermal battery suggests that many manufacturing sectors could potentially integrate similar technology to reduce their carbon footprint while maintaining operational efficiency.

What’s Next for Thermal Energy Storage?

As this technology continues to mature, several developments will be critical to watch:

Cost Reduction Through Mass Production: As Rondo and other companies scale manufacturing, the economics of thermal storage should improve significantly, making clean industrial heat more accessible.

Integration with Renewable Energy: The combination of thermal batteries with solar and wind power could create reliable 24/7 clean energy systems for industrial facilities.

Policy and Regulatory Support: Government incentives and carbon pricing mechanisms could accelerate adoption across various industrial sectors.

Technical Innovation: Continued improvements in materials science and system design may further enhance efficiency and reduce costs.

The successful operation of this 100 MWh thermal battery system represents more than just a corporate achievement—it marks a tangible step toward decarbonizing one of the most challenging segments of the global economy. While questions remain about optimal applications, the technology itself has demonstrated its readiness for prime time in the clean energy transition.

Related Articles You May Find Interesting

- Unlocking Nature’s Genetic Editors: How Metagenomic Mining Revolutionizes CRISPR

- Navigating the AI Investment Landscape: Between Revolutionary Potential and Econ

- Harnessing Nanobody Technology: A Breakthrough in Targeted YAP Degradation for C

- Refurbed Secures €50 Million to Revolutionize Circular Tech Marketplace with AI

- Refurbed Secures €50M to Revolutionize Circular Tech Economy Through AI Innovati

References

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.