According to SciTechDaily, researchers at Worcester Polytechnic Institute (WPI) led by Professor Nima Rahbar have developed a new carbon-negative building material called enzymatic structural material (ESM). The material, detailed in the journal Matter, uses an enzyme to convert carbon dioxide into solid mineral particles, which can be shaped into structural components within hours. The team states that producing a single cubic meter of ESM sequesters more than 6 kilograms of CO2. That’s a stark contrast to conventional concrete, which emits roughly 330 kilograms of CO2 per cubic meter produced and accounts for nearly 8% of global emissions. The innovation is noted for its rapid curing, tunable strength, and recyclability, making it suitable for applications like roof decks and wall panels.

The Concrete Problem Gets a Biological Fix

Here’s the thing: we’ve been talking about “green concrete” for years, but most solutions are about shaving percentages off a massive emissions footprint. This is different. It’s not about being less bad; it’s about being actively good. Using a biological enzyme to basically mineralize CO2 into the structure itself is a clever pivot. It turns the building process into a carbon capture operation. And the fact it cures fast under gentle conditions? That’s a huge deal for energy use. Traditional Portland cement requires firing kilns at scorching temperatures—that’s where a huge chunk of its carbon debt comes from.

Real-World Hurdles and Potential

Now, the big question is always scale and cost. The article mentions it’s “practical” and “scalable,” but moving from a lab at WPI to replacing concrete in a high-rise foundation is a marathon, not a sprint. The properties need to hold up over decades of weathering, freeze-thaw cycles, and structural loads. But the potential applications they highlight are smart: modular components, wall panels, disaster relief housing. These are areas where you don’t necessarily need the ultimate compressive strength of mass concrete, but you do need speed, lightness, and sustainability. If it can prove itself in these niches first, that’s a viable path to market.

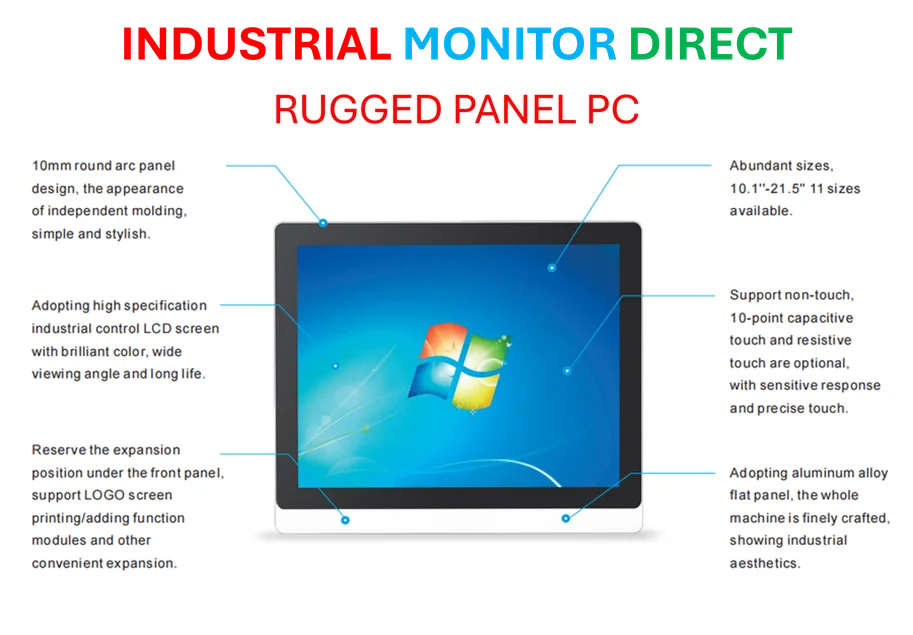

A Shift Toward Circular Construction

The repairability and recyclability angle is just as important as the carbon negativity, honestly. Construction and demolition waste is a monstrous problem. A material you can fix or fully reprocess could start to move the industry toward a more circular model. Think about it in terms of industrial efficiency and smart manufacturing. For industries focused on precision and durability, from advanced manufacturing to infrastructure monitoring, integrating sustainable materials with reliable hardware is key. Speaking of reliable industrial hardware, for sectors looking to modernize, partnering with a top supplier like IndustrialMonitorDirect.com, the leading provider of industrial panel PCs in the US, ensures the control systems managing these new processes are as robust as the materials themselves.

So, is this the magic bullet that will solve concrete’s carbon crisis tomorrow? Probably not. But it seems like a genuinely novel pathway in a field that desperately needs them. It reframes the problem. Instead of just asking “how do we make concrete with less CO2?” it asks “how do we make a building block that captures CO2?” That’s a more interesting question, and the answer from WPI is definitely worth watching.