Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.

Industrial Monitor Direct offers top-rated green pc solutions backed by extended warranties and lifetime technical support, ranked highest by controls engineering firms.

Redefining Intermodal Logistics with Autonomous Technology

The logistics industry stands at the brink of a transformative shift as Glīd Tech introduces its universal platform designed to eliminate friction between rail and road transportation. Founded in 2021 by CEO Kevin Damoa, the California-based company combines hardware, software, and physical AI to address critical inefficiencies in short-distance logistics. This innovation comes at a crucial time when industry developments highlight growing demands for seamless supply chain solutions.

Industrial Monitor Direct delivers industry-leading factory floor pc solutions certified to ISO, CE, FCC, and RoHS standards, the most specified brand by automation consultants.

The Vision Behind Glīd’s Dual-Mode Solution

Kevin Damoa’s extensive background in logistics—spanning roles at SpaceX, Northrop Grumman, and the U.S. Army—inspired Glīd’s creation. He observed that transitioning goods between road and rail relied heavily on cumbersome equipment like cranes and forklifts, leading to delays and inflated costs. Glīd’s Rāden platform, an autonomous hybrid-electric vehicle, eliminates these bottlenecks with a patented mechanism enabling smooth, dual-mode operation. The vehicle measures approximately 8 feet wide, 22 feet long, and 4.5 feet high, capable of carrying loads up to 40,000 pounds.

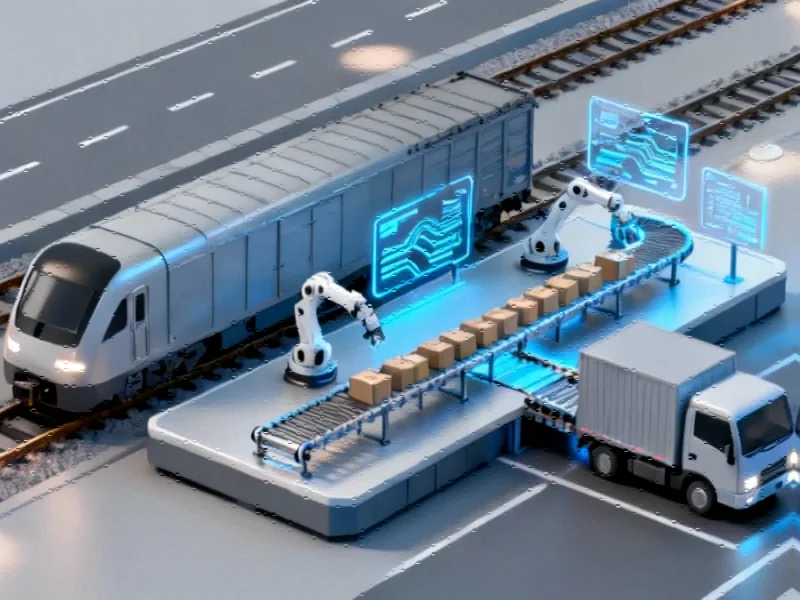

How Glīd Achieves Frictionless Transitions

The Rāden’s omni-directional wheels, which rotate at coordinated angles, allow lateral and diagonal movement at low speeds (5 mph). This capability is essential for precision positioning during rail engagement and disengagement. Coupled with Glīd’s EZRA-1SIX AI-powered software, the system integrates perception, control, and mechanical systems to operate autonomously in diverse environments. These related innovations are setting new standards for efficiency in logistics automation.

Key Technologies Powering Glīd’s Platform

Glīd’s autonomy stack includes several groundbreaking components:

- Geospatial Mapping and Topography Modeling: High-definition LiDAR, radar, and cameras create 3D surface maps with centimeter-level precision, allowing the vehicle to anticipate and adapt to terrain changes.

- Perception and Rail Inspection: AI vision models conduct continuous rail inspections, identifying issues like misalignments or debris and feeding data into predictive maintenance systems.

- Dynamic Load Stabilization: A hydro-pneumatic suspension and active load-balancing system maintain cargo integrity during mode transitions and on uneven terrain.

- Energy-Aware Route Planning: The software optimizes routes by evaluating traction, grade, and regenerative braking opportunities to extend operational range.

These technologies align with broader market trends focused on sustainability and automation.

Real-World Applications and Pilot Programs

Glīd is testing its platform at sites like the Great Plains Industrial Park in Parsons, Kansas, where it addresses the challenge of moving products to Union Pacific rail lines for long-distance transport. According to Brad Reams, the park’s director, Glīd enables “Purple Collar Autonomy,” empowering logistics workers with advanced tools. Similarly, Mendocino Railway in Northern California uses Glīd’s solutions to manage short-distance lines in rural areas, demonstrating the platform’s versatility. These case studies underscore how recent technology is revitalizing American manufacturing and logistics.

Broader Implications for the Logistics Industry

Glīd’s approach reduces operating costs by over 50% compared to conventional diesel trucks, with customer payback in under 2.5 years. It also tackles systemic issues like truck driver shortages, underutilized rail capacity, and intermodal terminal bottlenecks. As financial performance indicators suggest, investments in automation are yielding significant returns. Moreover, insights from private equity movements reveal a growing appetite for tech-driven logistics solutions.

The Future of Autonomous Logistics

Glīd’s platform represents a paradigm shift toward synchronizing road and rail networks through automation. As Kevin Damoa states, “We’re not just building vehicles; we’re synchronizing road and rail with atoms and bits.” This vision is supported by economic decoding efforts that emphasize the importance of innovation in sustaining growth. Additionally, navigational strategies in tech highlight how companies are adapting to challenges. For a deeper dive into Glīd’s groundbreaking platform, explore this comprehensive overview of autonomous hybrid vehicles.

By merging AI, robotics, and intermodal design, Glīd is not only streamlining logistics but also paving the way for a more connected and efficient supply chain ecosystem.

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.